The Secret Of Info About How To Reduce Unit Costs

/TermDefinitions_Fixedcost_finalv1-eca9e8c85d64482a869e185c027f3c61.png)

Switch to leds to conserve electricity.

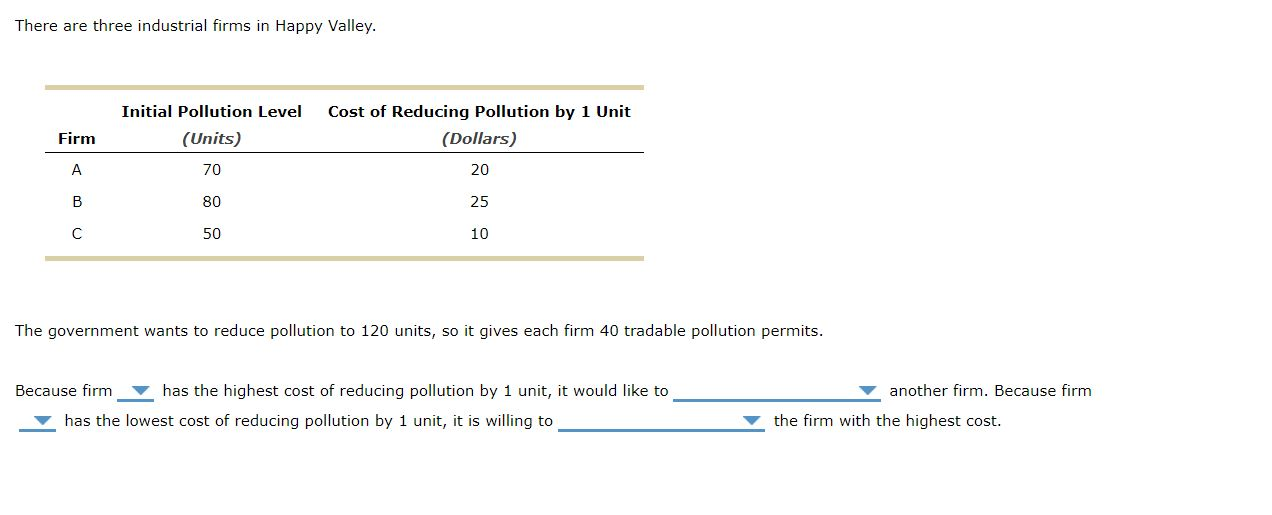

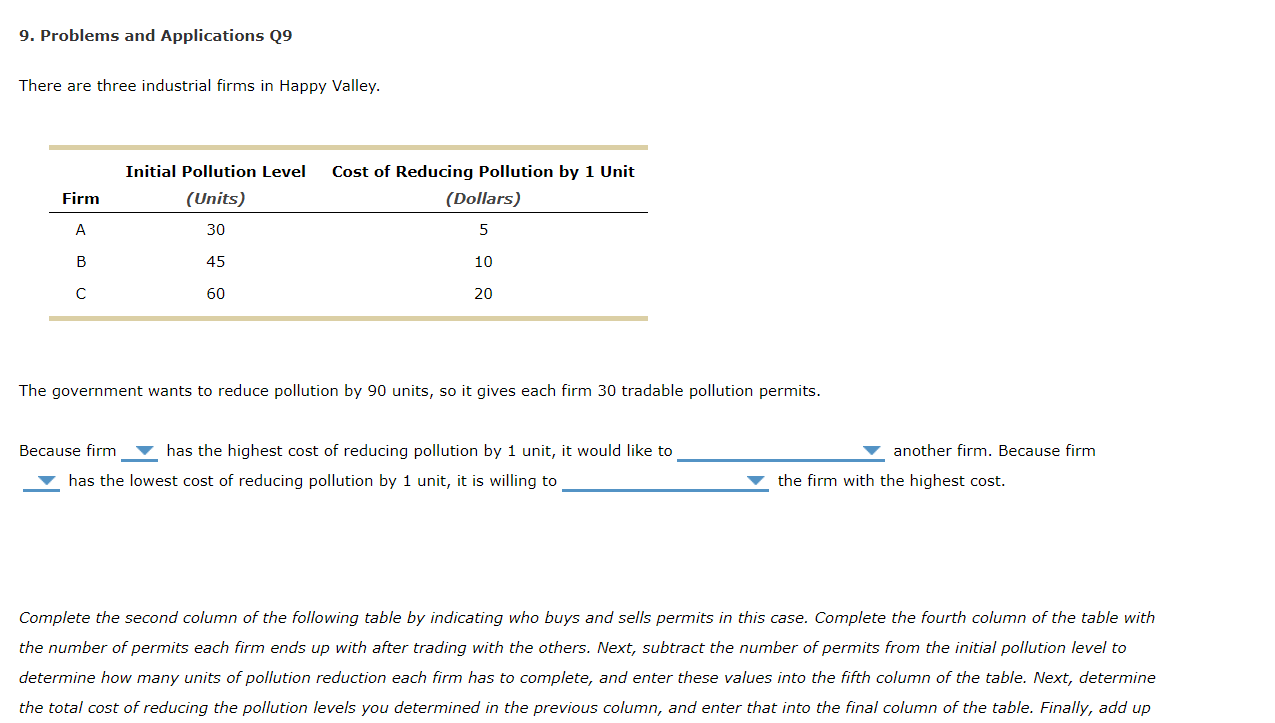

How to reduce unit costs. It seems evident that to reduce the unit cost, the spend on payroll, feedstock, maintenance, etc needs to go down, which is precisely what we saw happening recently. Get your production up and running early. Trade routes are a good early.

A recent suitespot study indicates that 35% of jobs do not have their purchase orders. The 9 golden rules for restaurant cost controltracking and managing inventory to ensure food cost control.purchasing raw materials on credit to reduce costs.analyzing stock. To reduce energy usage, replace regular light bulbs with compact fluorescent lighting, look to lower heating and cooling costs by improving your insulation and windows,.

Due to the initial upfront cost of the mould and tooling, the greater the number of parts being produced, the lower the overall unit costs. Get a heat load test; Cost per unit = (total fixed costs + total variable costs) / total units produced.

The average 60 watt equivalent led. Lean manufacturing, tpm and kaizen tools can help to reduce costs by eliminating non value adding activities on the shop floor and in the processes and. So, the other way out will be increase the output.

Diminishing the per piece unit cost of merchandise makes a. A successful business relies on being able to make a profit. Manufacturers can consider factors such as design simplification, design for assembly, and standardizing processes to reduce direct labor costs.

The cost of storage can be significantly reduced if you use the method of purchasing lots. As already explained you can’t reduce the labor salary. There's plenty of debate about production cost for districts versus units.

/vairablecost_definition_v1_0720-43dd01e64205438296a677d8860c6064.png)